The details that follow are standard details that depict proper detailing for exterior walls with an EIFS finish. The source of these details is from EIFS Industry Association (EIMA), or adapted from the concepts of Foam Sheathing Coalition (FSC). The intent is to serve as a guide. Final approval of detailing for a specific construction project is the right and responsibility of the Architect of Record.

EXTERIOR INSULATION FINISH SYSTEM SOLUTIONS

PARAPET DETAIL

GENERAL NOTES

- Provide insulation and finish systems to meet EIMA Specifications. Installation of insulation and finish system shall be in accordance to EIMA’s Guide to Exterior Insulation & Finish System Construction.

- Provide air/water barrier compatible to EIFS. Air/water barrier to be continuous from face of exterior wall, over parapet, and onto roof membrane.

- Check with Underwriters Laboratories for specific air/water barrier systems.

- Face of coping shall extend a minimum of 2-1/2” below upper edge of EIFS.

- Follow SFIA Technical Guide for Cold-Formed Steel Framing Products for specific depth, thickness, and spacing of structural studs and roof joists.

- Consult with specialty structural engineer for structural stud and roof design.

- Check local codes and mechanical engineer for vapor retarder type and location.

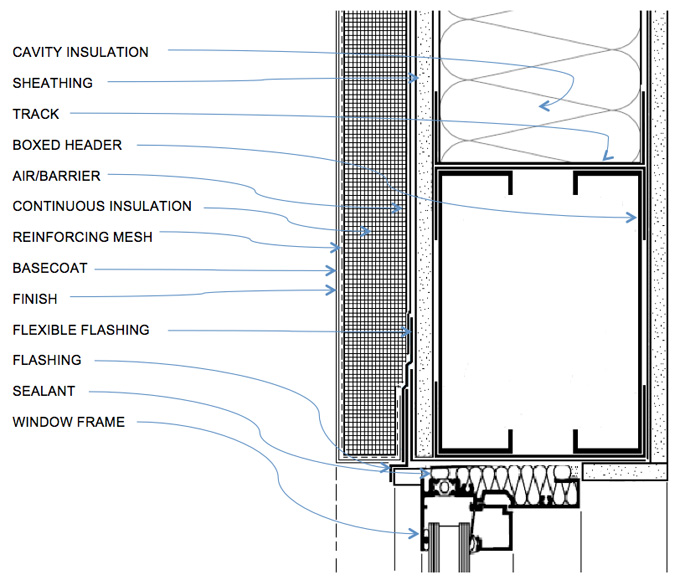

WINDOW HEAD DETAIL

GENERAL NOTES

- Provide insulation and finish systems to meet EIMA Specifications. Installation of insulation and finish system shall be in accordance to EIMA’s Guide to Exterior Insulation & Finish System Construction.

- Cavity Insulation omitted from box header for clarity.

- Provide air/water barrier compatible to EIFS. Air/water barrier to be continuous.

- Wrap window rough opening with appropriate flexible flashing material, check EIMA Guidelines.

- Check with Underwriters Laboratories for specific air/water barrier systems.

- Follow SFIA Technical Guide for Cold-Formed Steel Framing Products for specific depth, thickness, and spacing of structural studs.

- Protect corner of interior gypsum panel panels with appropriate corner reinforcement.

- Consult with specialty structural engineer for structural stud and boxed header design.

- Check local codes and mechanical engineer for vapor retarder type and location.

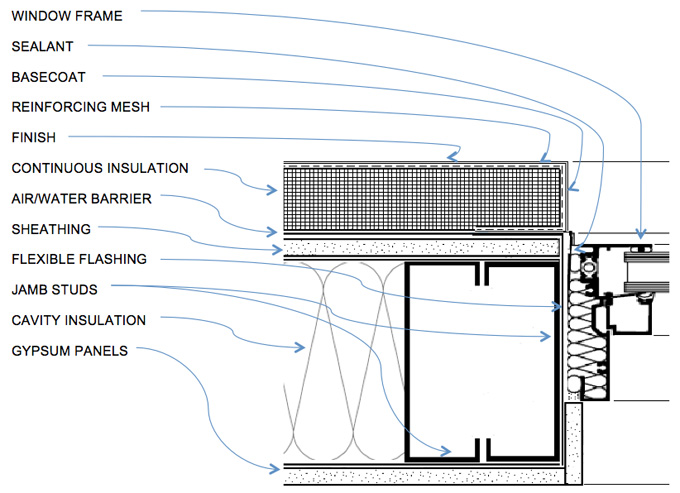

WINDOW JAMB DETAIL

GENERAL NOTES

- Provide insulation and finish systems to meet EIMA Specifications. Installation of insulation and finish system shall be in accordance to EIMA’s Guide to Exterior Insulation & Finish System Construction.

- Cavity Insulation omitted from boxed jamb for clarity.

- Provide air/water barrier compatible to EIFS. Air/water barrier to be continuous.

- Wrap window rough opening with appropriate flexible flashing material, check EIMA Guidelines.

- Check with Underwriters Laboratories for specific air/water barrier systems.

- Protect corner of interior gypsum panel panels with appropriate corner reinforcement.

- Follow SFIA Technical Guide for Cold-Formed Steel Framing Products for specific depth, thickness, and spacing of structural studs.

- Consult with specialty structural engineer for structural stud and jamb stud design.

- Check local codes and mechanical engineer for vapor retarder type and location.

WINDOW SILL DETAIL

GENERAL NOTES

- Provide insulation and finish systems to meet EIMA Specifications. Installation of insulation and finish system shall be in accordance to EIMA’s Guide to Exterior Insulation & Finish System Construction.

- Provide air/water barrier compatible to EIFS. Air/water barrier to be continuous from face of exterior wall sheathing through rough opening.

- Wrap window rough opening with appropriate flexible flashing material, check EIMA Guidelines.

- Install sill pan according to EIMA guidelines and provide positive drainage to exterior.

- Check with Underwriters Laboratories for specific air/water barrier systems.

- Protect corner of interior gypsum panel panels with appropriate corner reinforcement.

- Follow SFIA Technical Guide for Cold-Formed Steel Framing Products for specific depth, thickness, and spacing of structural studs.

- Consult with specialty structural engineer for structural stud system design.

- Check local codes and mechanical engineer for vapor retarder type and location.

INTERMEDIATE FLOOR BALLOON FRAMING DETAIL

GENERAL NOTES

- Provide insulation and finish systems to meet EIMA Specifications. Installation of insulation and finish system shall be in accordance to EIMA’s Guide to Exterior Insulation & Finish System Construction.

- Provide air/water barrier compatible to EIFS. Air/water barrier to be continuous from face of exterior wall through rough opening.

- Check with Underwriters Laboratories for specific air/water barrier systems.

- Follow SFIA Technical Guide for Cold-Formed Steel Framing Products for specific depth, thickness, and spacing of structural studs and floor joists.

- Consult with specialty structural engineer for structural stud and floor system design.

- Check local codes and mechanical engineer for vapor retarder type and location.

FOUNDATION DETAIL

GENERAL NOTES

- Provide insulation and finish systems to meet EIMA Specifications. Installation of insulation and finish system shall be in accordance to EIMA’s Guide to Exterior Insulation & Finish System Construction.

- Provide air/water barrier compatible to EIFS. Air/water barrier to be continuous.

- Check with Underwriters Laboratories for specific air/water barrier systems.

- Follow SFIA Technical Guide for Cold-Formed Steel Framing Products for specific depth, thickness, and spacing of structural studs.

- Consult with specialty structural engineer for structural stud design.

- Check local codes and mechanical engineer for vapor retarder type and location.

- Provide termite separation as required by local code.

- Foundation insulation omitted for clarity. Follow local energy code requirements.

While reasonable effort has been made to ensure the accuracy of this information, we assume no liability for any errors or omissions on these pages. Please verify all information with the organizations mentioned above. It is the right and responsibility for the architect of record to make final material/system selection.