The details that follow are standard details that depict proper detailing for interior non-load bearing partitions. The source of these details is either ASTM or the Gypsum Association. The intent is to serve as a guide. Final approval of detailing for a specific construction project is the right and responsibility of the Architect of Record.

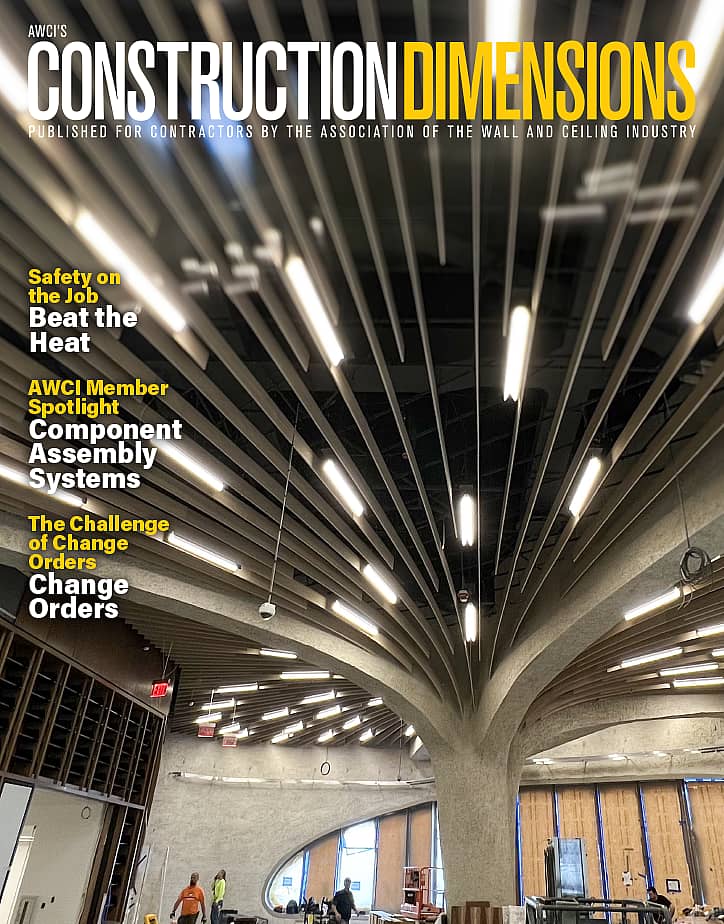

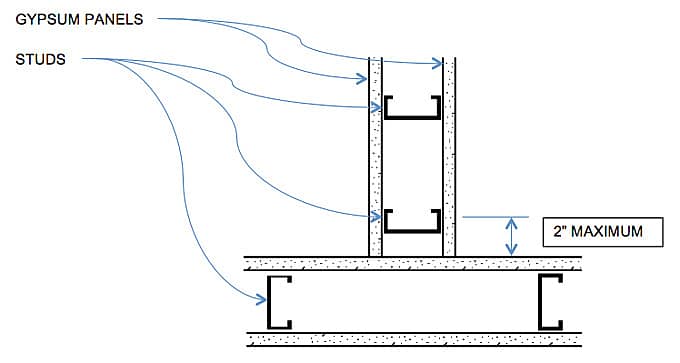

ACOUSTICAL HEAD – OF- WALL

- Continuous bead of acoustical sealant in contact with gypsum panels, track, and structure.

- To allow for differential movement, no mechanical fasteners between gypsum panels, track, and stud.

- Check with Underwriters Laboratories for specific fire rated head-of-wall designs.

- Source: Gypsum Association, GA-600 Fire Resistance Design Manual.

- Attach track to structure with appropriately sized and spaced fasteners.

- Nominal 3/8” gap between top of gypsum panels to bottom of structure.

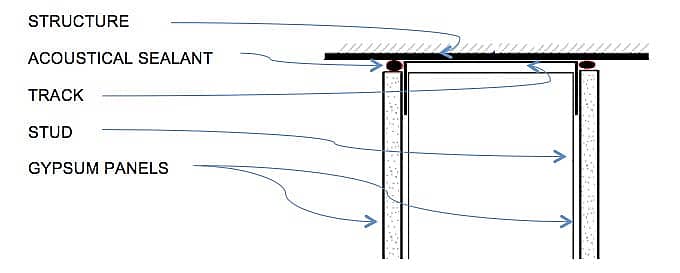

WALL BASE – NON STRUCTURAL

GENERAL NOTES

- Sealant required for acoustical performance, smoke control, and fire resistance. Check specific Underwriters Laboratories designs for specific sealant types.

- Attach track to structure with appropriately sized and spaced fasteners.

- Nominal 3/8” gap between bottom of gypsum panels to top of structure.

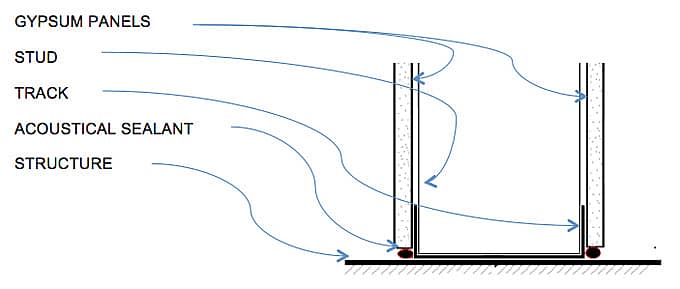

PARTITION CORNER DETAIL

GENERAL NOTES

- Source: ASTM C754 Standard Specification for Installation of Steel Framing Members to Receive Screw-Attached Gypsum Panel Products.

- Use corner reinforcement (joint compound and trim) to protect outer gypsum edge corner.

PARTITION CORNER DETAIL

GENERAL NOTES

- SOURCE: ASTM C754 Standard Specification for Installation of Steel Framing to Receive Screw-Attached Gypsum Panel Products.

- Use corner reinforcement (joint compound and trim) to protect outer gypsum panel edge corner.

ABUTTING PARTITION DETAIL

GENERAL NOTES

- Source: ASTM C754 Standard Specification for Installation of Steel Framing Members to Receive Screw-Attached Gypsum Panel Products.

- Use corner reinforcement (joint compound and tape) to finish inner gypsum edge corners..

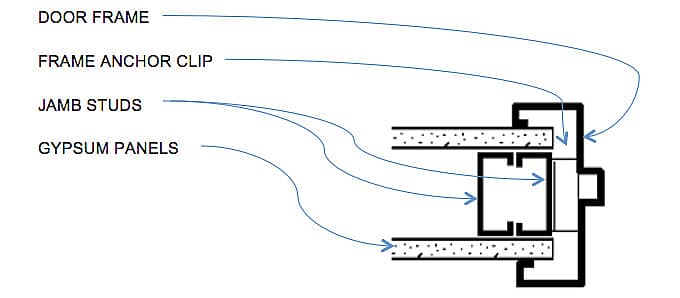

DOOR FRAME DETAIL

GENERAL NOTES

- Position jamb studs from floor to structure and attach to track top and bottom.

- Determine if special details are required to accommodate slab deflection.

- Fabricate door header from track sections and attach to jamb studs.

- Number and steel thickness of jamb studs based on size of opening and weight of doors.

- Less than full height door frames require control joints in gypsum panels over door frame.

While reasonable effort has been made to ensure the accuracy of this information, we assume no liability for any errors or omissions on these pages. Please verify all information with the organizations mentioned above. It is the right and responsibility for the architect of record to make final material/system selection.