Special Section Sponsored by Grabber

Grabber fasteners have been making professionals more productive and profitable for over 50 years. Investing in Grabber products means you can expect less material waste, greater worker productivity and fewer tasks that run up labor costs.

A fastener is a small thing in a construction project. But how it performs can have a big impact on productivity and ultimate cost. Just consider that a fastener’s cost in place is often four to five times as much as the cost of the fastener itself.

And it might take just a second or two to drive a screw, but multiply that by the number of screws in a whole project and that install time becomes significant. Simply put, the more fasteners your crew can drive per hour, the more efficient and profitable you can be. Grabber fasteners drive faster, seat better and are less likely to cam-out and spin-out. This all adds up to getting on to the job, getting projects done and on to the next job faster. This is especially critical on today’s job sites.

The Highest Fastener Manufacturing Standards

No one has higher manufacturing standards than Grabber. It starts with the quality of our high-grade SAE 1022 steel. This superior steel makes stronger heads, and threads that are less likely to break or bend.

We also change our dies much more frequently during the manufacturing process. This translates into consistent performance fastener to fastener, sharper threads, faster drilling times—and tight recesses for better bit engagement, less wobbling and fewer cam-outs.

In addition, Grabber heat treats fewer fasteners in a batch, ensuring every screw is hardened evenly. Our heat-treating standards means you can expect consistent performance—with heads that don’t snap off and screws that don’t bend.

Higher manufacturing standards mean your team will spend less time performing do-overs and more time making you money. With Grabber fasteners on the job, installers can drive more screws and install more drywall with less wasted material. They’ll be able to get the job done and move on to the next one in less time, which is especially critical in these times when trade stacking is increasingly the norm.

Innovations Like PanelMax Make Your Job Easier

Grabber is constantly innovating ways to make your team more efficient. The double bugle head design of our SCAVENGER® HEAD fasteners seat cleanly into drywall, eliminating paper burrs and reducing finishing costs. And the precision design of our VECTOR™ POINT fasteners penetrate metal up to 50% faster than other products.

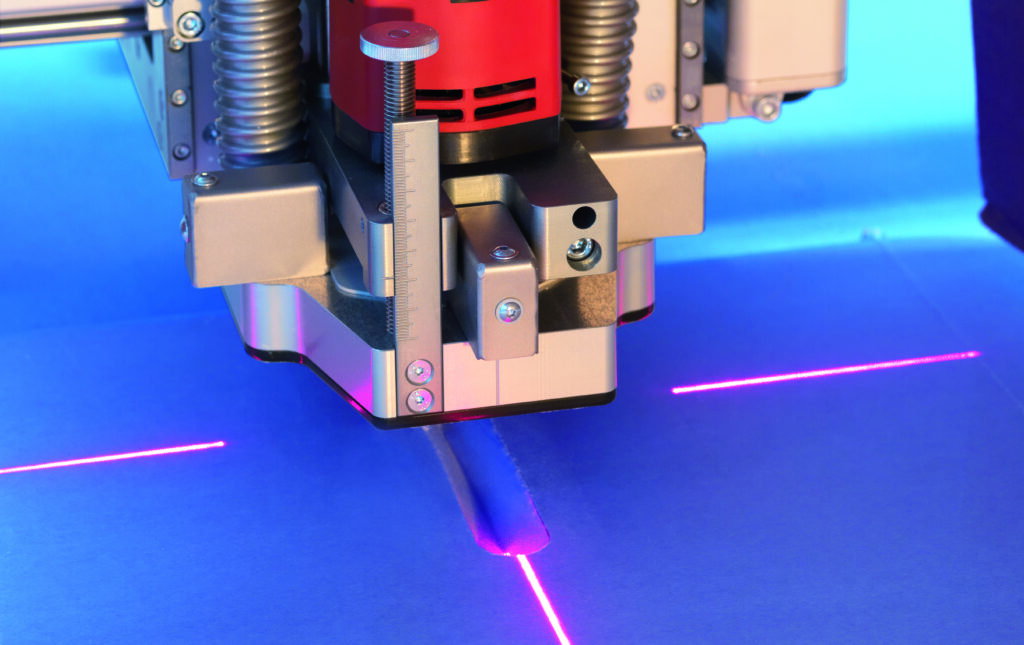

But Grabber innovation goes beyond fasteners. Just look at the revolutionary PanelMax panel fabrication technology. With PanelMax advanced panel fabrication technology, drywall assemblies can be pre-assembled and ready to install when needed. Parts can be fabricated and duplicated off-site and then delivered and installed on the job site just in time. Quick, easy and just in time.

PanelMax is a revolutionary system that makes creating intricate shapes and assemblies from drywall much more affordable. Projects that require a lot of manual cutting or that have complex curves have always been cumbersome and time-consuming for builders. Now even the most challenging assemblies can be completed more efficiently with less finishing.

PanelMax mills a perfect corner, using gypsum, wood and plastic or even cement board. Precision engineered groves allow material to be fabricated into rigid and precisely aligned assemblies. PanelMax milled corners, especially drywall, are clean and precise minimizing the need for additional finishing materials, saving time, labor and material costs and making the most detailed cuts easy and accurate.

PanelMax applications include wall construction, stencil cut-outs, duct linings, ceiling construction, columns and lamellar cutouts, 90-degree corners and prefabricated parts. To see more applications and see how PanelMax can save you time an money on your next job, go to grabberpro.com/PanelMax.

Solving Problems, Saving Costs

Grabber’s boots-on-the-ground sales force has industry experience and an unparalleled knowledge of tools, fasteners and applications. When you call Grabber, you get quality products and top-notch advice that saves you time and money while making your company more competitive than ever. In a word, we’re talking value. You deserve it. And we promise it. Unconditionally.

Visit grabberpro.com/professional-grade to learn more.